Analog-to-Digital Converters (ADCs) are a cornerstone of embedded systems, bridging the gap between the analog world and digital processing. From monitoring environmental sensors to processing audio signals, ADCs play a critical role in embedded applications. However, achieving accurate ADC measurements is not always straightforward. Engineers often encounter inaccuracies due to design flaws, noise, and improper configurations, leading to unreliable data and suboptimal system performance.

In this article, we’ll explore the common pitfalls that lead to inaccurate ADC measurements, along with practical fixes to improve accuracy. Whether you’re a seasoned embedded engineer or new to ADCs, this guide will help you understand and address the challenges associated with ADC implementation.

How ADCs Work: A Quick Refresher

An ADC converts an analog input voltage into a digital representation. This process typically involves:

- Sampling: Measuring the analog signal at regular intervals.

- Quantization: Mapping the sampled value to the nearest digital level.

- Encoding: Representing the quantized value in binary format.

The accuracy of an ADC depends on several factors, including resolution, sampling rate, reference voltage, and noise levels. While ADC specifications often look great on paper, real-world implementations can introduce errors that degrade measurement accuracy.

Common Pitfalls in ADC Measurements

1. Noise in the System

Problem: Analog signals are susceptible to noise, which can corrupt ADC measurements. Sources of noise include:

- Electromagnetic interference (EMI) from nearby components.

- Power supply noise, especially in high-frequency switching circuits.

- Crosstalk from adjacent PCB traces.

Symptoms:

- Fluctuating ADC readings even with a stable input voltage.

- Measurements affected by nearby components (e.g., motors, RF transmitters).

Fixes:

- Use Decoupling Capacitors: Place decoupling capacitors (e.g., 0.1 µF and 1 µF) near the ADC’s power supply pins to filter high-frequency noise.

- Shield Sensitive Signals: Use grounded enclosures or shields to protect analog traces from EMI.

- Improve PCB Layout: Separate analog and digital ground planes, and route analog traces away from noisy signals.

2. Improper Grounding

Problem: Poor grounding practices can create ground loops, voltage offsets, and noise, all of which degrade ADC accuracy.

Symptoms:

- Drift in ADC readings.

- Different measurements for the same input voltage under varying conditions.

Fixes:

- Use a Single-Point Ground: Connect analog and digital grounds at a single point near the ADC or microcontroller.

- Star Grounding: Route all ground connections to a central point to minimize loops.

- Minimize Ground Bounce: Use low-impedance ground connections and wide traces to reduce fluctuations.

3. Mismatched Signal and ADC Input Range

Problem: If the input signal’s range doesn’t match the ADC’s input range, the ADC cannot utilize its full resolution, leading to quantization errors.

Symptoms:

- Clipped or saturated ADC readings.

- Low-resolution measurements due to poor dynamic range utilization.

Fixes:

- Use Signal Conditioning Circuits: Add an amplifier or attenuator to scale the input signal to match the ADC’s input range.

- Adjust Reference Voltage: Configure the ADC’s reference voltage to better match the input signal range.

4. Reference Voltage Instability

Problem: The ADC’s reference voltage determines the resolution of each digital step. An unstable or noisy reference voltage leads to fluctuating ADC measurements.

Symptoms:

- Inconsistent readings even with a steady input signal.

- Measurements that vary with power supply fluctuations.

Fixes:

- Use a Stable Reference Voltage Source: Use a precision voltage reference IC instead of the microcontroller’s internal reference.

- Decouple the Reference Pin: Place a capacitor (e.g., 10 µF) close to the ADC’s reference pin to filter noise.

- Avoid High-Impedance Sources: Ensure the reference voltage source can drive the required current without voltage drops.

5. Insufficient Sampling Rate

Problem: The Nyquist theorem states that the sampling rate must be at least twice the highest frequency in the input signal. Violating this rule leads to aliasing, where high-frequency components distort the measurement.

Symptoms:

- Incorrect signal representation.

- Artifacts or unexpected waveforms in the digital signal.

Fixes:

- Increase the Sampling Rate: Choose a sampling rate at least 2.5 times the highest input frequency for added margin.

- Use an Anti-Aliasing Filter: Place a low-pass filter before the ADC to attenuate frequencies higher than half the sampling rate.

6. Incorrect Clock Configuration

Problem: ADCs require a clock signal for proper operation. An incorrectly configured clock can lead to timing errors, missed samples, or poor conversion accuracy.

Symptoms:

- Missing or incorrect ADC readings.

- Degraded accuracy under high sampling rates.

Fixes:

- Check the Datasheet: Verify the ADC clock speed meets the recommended range specified by the manufacturer.

- Optimize Clock Dividers: Use appropriate clock dividers to achieve a stable and precise clock frequency.

- Avoid Jitter: Minimize clock jitter by using a high-quality oscillator or crystal.

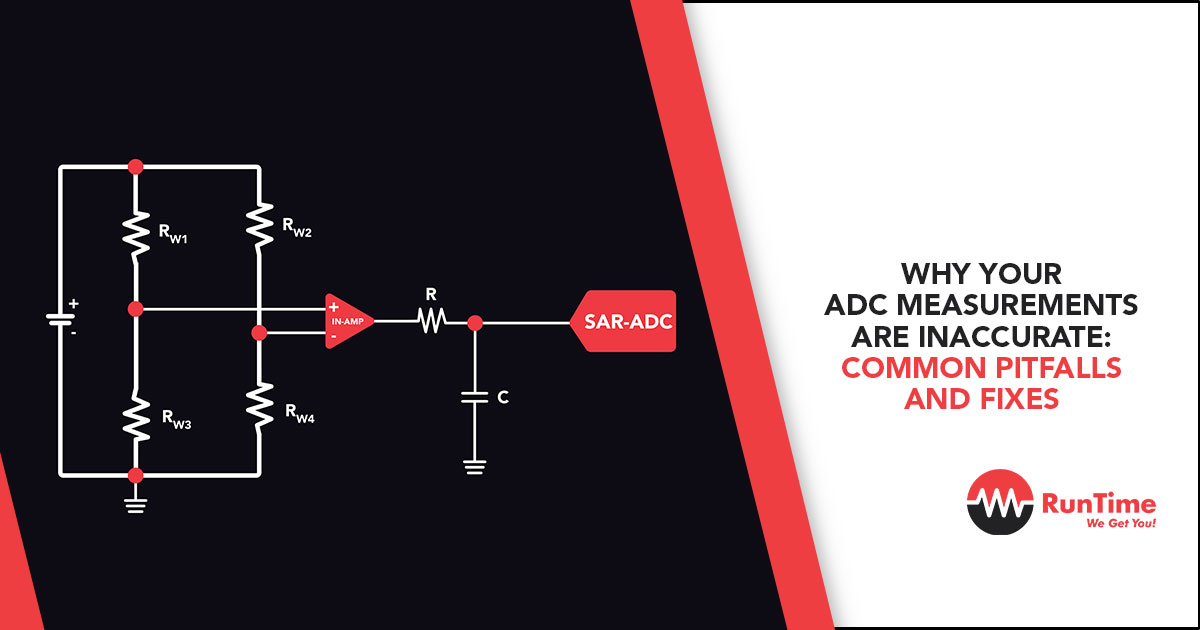

7. Loading Effects

Problem: ADC inputs are high-impedance by design, but driving them directly from a high-impedance source can cause errors due to input loading effects.

Symptoms:

- Slow response to changes in the input signal.

- Incorrect readings when the input signal changes rapidly.

Fixes:

- Add a Buffer Amplifier: Use an operational amplifier in a voltage follower configuration to drive the ADC input.

- Match Impedances: Ensure the source impedance is significantly lower than the ADC’s input impedance.

8. Temperature Variations

Problem: ADC performance can vary with temperature, affecting gain, offset, and reference voltage stability.

Symptoms:

- Gradual drift in measurements over time or with changes in ambient temperature.

- Inconsistent readings across different operating conditions.

Fixes:

- Use Temperature-Stable Components: Choose ADCs and reference ICs with low temperature coefficients.

- Implement Temperature Compensation: Use a temperature sensor to monitor and compensate for temperature-induced errors.

- Design for Thermal Stability: Minimize temperature gradients on the PCB by placing heat-generating components away from sensitive analog circuitry.

9. Software Errors

Problem: Even with proper hardware design, incorrect firmware can cause ADC inaccuracies due to:

- Improper ADC configuration (e.g., resolution, sampling time).

- Failure to handle ADC calibration data.

- Incorrect scaling of raw ADC values.

Symptoms:

- Systematic errors in measurements.

- Misinterpretation of ADC data.

Fixes:

- Calibrate the ADC: Use factory calibration values or implement a custom calibration routine to correct gain and offset errors.

- Scale Values Correctly: Ensure raw ADC readings are scaled based on the reference voltage and resolution.

- Verify Configuration Settings: Double-check ADC initialization code for correct settings.

10. Quantization and Resolution Limitations

Problem: The resolution of an ADC determines the smallest measurable change in input voltage. Inadequate resolution can lead to quantization errors and insufficient precision.

Symptoms:

- Loss of detail in measurements.

- Stepped output instead of a smooth response.

Fixes:

- Choose a Higher-Resolution ADC: Use a 16-bit ADC instead of a 10-bit ADC for more precise measurements.

- Use Averaging: Average multiple ADC samples to reduce quantization noise.

- Scale the Signal: Amplify small signals to utilize the ADC’s full input range.

Practical Tips for Accurate ADC Measurements

- Separate Analog and Digital Grounds: Keep analog and digital circuits isolated to reduce noise coupling. Connect them at a single point to avoid ground loops.

- Keep Analog Traces Short: Minimize the length of analog signal traces on the PCB to reduce susceptibility to noise.

- Use Twisted Pairs or Shielded Cables: For long signal paths, use twisted pairs or shielded cables to minimize EMI.

- Perform Regular Calibration: Periodically calibrate the ADC to account for component aging and environmental changes.

- Monitor Power Supply Quality: Ensure a clean and stable power supply by using low-noise regulators and sufficient decoupling capacitors.

- Use Differential ADCs for Noisy Environments: Differential ADCs reject common-mode noise and are ideal for industrial applications.

- Document and Validate Assumptions: Clearly document ADC configurations, reference voltages, and scaling factors. Validate them during testing.

Case Studies: Real-World ADC Challenges

Case Study 1: Sensor Measurement Drift

Scenario: An industrial sensor’s ADC measurements showed drift over time. Diagnosis:

- Unstable reference voltage.

- Noise from adjacent power supply traces. Solution:

- Replaced the reference voltage source with a precision IC.

- Rerouted power supply traces away from analog signals.

Case Study 2: Inconsistent Temperature Sensor Readings

Scenario: A temperature sensor connected to an ADC produced inconsistent readings across different devices. Diagnosis:

- High-impedance sensor output caused loading effects on the ADC input. Solution:

- Added a buffer amplifier between the sensor and the ADC.

Case Study 3: Aliasing in Audio Signal

Scenario: An audio application experienced aliasing artifacts in ADC measurements. Diagnosis:

- Insufficient sampling rate. Solution:

- Increased the sampling rate and added an anti-aliasing filter.

Conclusion

Achieving accurate ADC measurements in embedded systems requires a holistic approach, addressing hardware, software, and environmental factors. By understanding common pitfalls—such as noise, grounding issues, and sampling errors—and applying the recommended fixes, engineers can significantly improve the accuracy and reliability of ADC-based systems.

Accurate ADC measurements are the foundation of many embedded applications, and taking the time to optimize your design will pay dividends in system performance and customer satisfaction. With the right tools, techniques, and best practices, you can ensure your ADC measurements are as precise and reliable as possible.