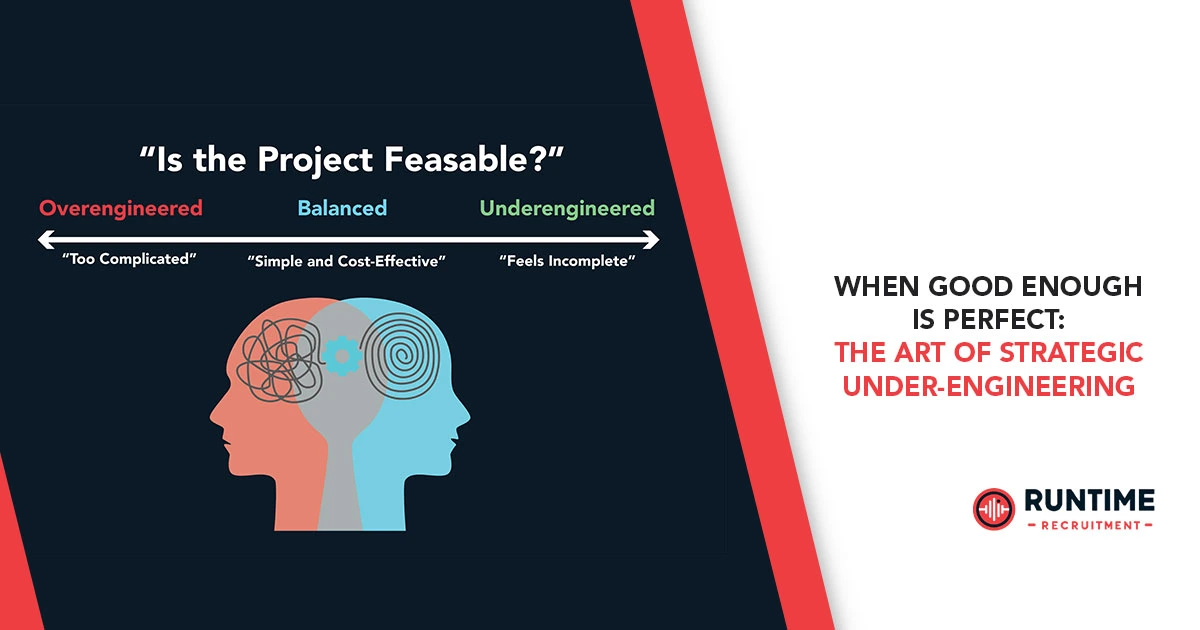

In the relentless pursuit of technological perfection, embedded engineers often find themselves on a treadmill of over-engineering. We’re taught to build for every conceivable scenario, to create systems that are robust enough to withstand an apocalypse, and to optimize every single line of code for maximum efficiency. This mindset, while rooted in good intentions, can lead to bloated, complex, and unnecessarily expensive products. But what if I told you there’s a powerful, often overlooked philosophy that can lead to faster development cycles, lower costs, and more focused innovation? It’s the art of strategic under-engineering.

Strategic under-engineering isn’t about laziness or cutting corners. It’s a deliberate and thoughtful approach to design where you consciously choose the simplest, most effective solution that meets the project’s core requirements, and nothing more. It’s about recognizing that “good enough” is often not a compromise, but the optimal solution. This isn’t a new concept; it’s a foundational principle of agile development and lean manufacturing. Yet, in the world of embedded systems, where every clock cycle and byte of memory feels sacred, it’s a difficult habit to break.

The siren song of perfection is strong. We want our firmware to be a masterpiece of elegant code, our hardware to be a marvel of integrated components, and our systems to be future-proofed against every eventuality. However, this pursuit often leads to a phenomenon known as “featuritis”. We add features that users don’t need, we optimize code that will never be a bottleneck, and we design hardware for performance levels that will never be reached in the real world. The result? Extended development timelines, ballooning budgets, and a product that is so complex that it becomes difficult to maintain and debug.

The Over-Engineering Trap: A Cautionary Tale

Let’s imagine a hypothetical project: a simple smart thermostat.

The Over-Engineered Approach:

An over-engineered design might include:

- A powerful 32-bit microcontroller with an ARM Cortex-M4 core, capable of running a real-time operating system (RTOS) like FreeRTOS.

- A high-resolution color LCD touch screen with a complex graphical user interface (GUI).

- A Wi-Fi module supporting the latest 802.11ax standard, along with Bluetooth Low Energy (BLE) and Zigbee for future expansion.

- An array of high-precision sensors for temperature, humidity, and air quality, even though the core function only requires temperature sensing.

- A robust, custom-designed power supply with a wide input voltage range and multiple protection circuits.

- A firmware architecture designed to be modular and scalable, with multiple task schedulers and inter-process communication (IPC) mechanisms.

- An extensive logging and debugging framework, capturing every possible event and state.

The engineers might spend months, or even a year, meticulously crafting this complex system. They’ll write thousands of lines of code, navigate the complexities of multiple wireless protocols, and spend a significant portion of the budget on high-end components. The final product would be a technological marvel, but it would also be incredibly expensive, slow to market, and likely plagued with integration challenges.

The Strategically Under-Engineered Approach:

Now, let’s look at the same project with a strategic under-engineering mindset. The core requirement is to accurately measure and control the room’s temperature.

- A simple 8-bit or 16-bit microcontroller (like an AVR or a lower-end STM32) with a minimal footprint. It’s powerful enough to read a temperature sensor and drive a relay.

- A simple monochrome seven-segment display, or perhaps a small, low-resolution character LCD. The user can adjust the temperature with a few physical buttons.

- A simple Wi-Fi module with a basic TCP/IP stack for remote control, using a protocol like MQTT. No need for BLE or Zigbee unless they’re explicitly required for the product’s core functionality.

- A standard thermistor for temperature sensing, which is accurate enough for consumer use.

- A simple, off-the-shelf power supply module.

- A firmware architecture built on a simple state machine, with a main loop handling all tasks. No RTOS is necessary.

- Minimal logging, only for critical errors, to save memory and processing power.

This version of the thermostat is fast to develop, inexpensive to manufacture, and incredibly reliable. It does exactly what it needs to do, and nothing more. The user gets a functional, affordable product, and the company gets to market quickly, capturing a crucial competitive advantage.

The Pillars of Strategic Under-Engineering

Adopting this philosophy requires a shift in mindset, a discipline to resist the temptation of “just in case” features. Here are the core pillars that guide the strategic under-engineer:

1. Define the Minimal Viable Product (MVP) and Stick to It

This is the cornerstone of the entire philosophy. Before you write a single line of code or draw a schematic, you must have a crystal-clear definition of the MVP. What is the absolute minimum set of features that makes your product useful and solves the user’s problem? Every decision you make should be measured against this definition. If a feature or component doesn’t contribute directly to the MVP, it gets cut. This requires a strong product manager or team leader who can enforce this discipline and resist scope creep.

For example, a smart thermostat’s MVP is:

- Read ambient temperature.

- Allow the user to set a target temperature.

- Control a heating/cooling system to reach the target temperature.

- Provide a simple user interface to view and change the temperature.

Everything else—air quality sensors, a full-color touch screen, voice control—is a luxury that can be added in a future iteration, if the market demands it.

2. Embrace the “Rule of 80/20”

The Pareto Principle, or the 80/20 rule, states that roughly 80% of the effects come from 20% of the causes. In engineering, this translates to: 80% of your product’s value comes from 20% of its features. Strategic under-engineering is about identifying and focusing on that critical 20%.

For example, a high-performance microcontroller might offer a multitude of peripherals, but you only need a UART and a few GPIOs. Instead of choosing a complex chip with an overwhelming datasheet, choose a simpler one that provides exactly what you need. The time and effort saved in learning and debugging the extra peripherals can be significant.

3. Choose Off-the-Shelf over Custom Design

Unless your core value proposition is in a custom hardware component, always default to off-the-shelf solutions. Need a power supply? Don’t design a custom buck converter; buy a pre-certified module. Need a wireless module? Don’t design your own RF front-end; use a certified module from a reputable manufacturer. This dramatically reduces design time, lowers component cost, and accelerates the certification process (FCC, CE, etc.). The small premium you pay for a pre-built module is almost always less than the cost of your time and the risk of a custom design failure.

4. Simplify Your Software Architecture

Complex software architectures are a major source of bugs, performance issues, and maintenance nightmares. The strategic under-engineer opts for the simplest possible software design.

- Ditch the RTOS if you don’t need it. A simple super-loop or state machine can handle many tasks efficiently. An RTOS adds complexity, requires more memory, and introduces a whole new class of synchronization and debugging challenges.

- Avoid premature optimization. As Donald Knuth famously said, “Premature optimization is the root of all evil.” Write clear, readable code first. Only optimize the parts of the code that are proven to be performance bottlenecks, and only when a profiler shows they are a problem.

- Use lightweight libraries. Instead of a bloated library that does everything, look for a lightweight, focused library that only handles the task you need. If a library is too big, consider writing your own simple, focused implementation.

5. Prioritize Reliability and Maintainability

Strategic under-engineering isn’t about making a shoddy product. In fact, simpler systems are often more reliable and easier to maintain. With fewer components and less code, there are fewer points of failure. When a bug does occur, it’s easier to isolate and fix. This leads to a more robust final product and a better long-term user experience. The simplicity of the design itself becomes a form of engineering excellence.

The Payoff: Why Less is More

The benefits of strategic under-engineering are tangible and impactful:

- Faster Time to Market: By focusing only on the essentials, you can get a functional product to market in a fraction of the time. This is a critical competitive advantage in a fast-paced industry.

- Reduced Costs: Simpler hardware and software mean fewer components, less expensive manufacturing, and a smaller engineering team.

- Higher Quality and Reliability: Less complexity means fewer bugs and a more stable product. A simpler system is easier to test and debug thoroughly.

- Increased Agility: A simple, focused design is much easier to iterate on and pivot. If user feedback requires a change, a simple architecture can adapt much faster than a complex, monolithic one.

- Better User Experience: A product that is simple and focused on its core function is often easier for the user to understand and operate. The absence of unnecessary features reduces cognitive load.

A Modern Example: The Rise of IoT with Minimalist Design

Consider the countless low-cost IoT sensors and devices on the market today. Many of these devices are a masterclass in strategic under-engineering. They use a low-power microcontroller, a simple radio (like LoRa or Zigbee), and a basic sensor. The entire device is designed to do one thing—sense a specific data point and transmit it—with a battery life measured in years. They don’t have a color screen, a complex OS, or a custom power supply. They are a perfect example of how a “good enough” design can be the ideal design for a specific use case.

Conclusion: A New Way to Think About Excellence

The next time you start a new project, take a moment to ask yourself: “What is the absolute minimum I need to make this work?” Challenge every component, every line of code, and every feature. Be a ruthless editor of your own design.

Strategic under-engineering isn’t a sign of a lazy engineer; it’s a sign of a disciplined, experienced, and confident engineer. It’s the ability to see past the glamour of complexity and appreciate the quiet power of simplicity. It’s the wisdom to know when “good enough” is not just acceptable, but perfect. In our field, where we are constantly pushed to do more, a truly innovative engineer is one who understands the profound power of doing less.

Are you an embedded engineer passionate about creating elegant, efficient solutions? Do you believe in the power of strategic under-engineering to build incredible products?

At RunTime Recruitment, we connect top-tier embedded engineers with companies that value innovation, efficiency, and a lean approach to product development. We understand the unique challenges and rewards of this field, and we’re here to help you find your next great opportunity.

Connect with us today to find a role where your skills and philosophy are not just appreciated, but celebrated. Your perfect job is just a conversation away.