The digital world is awash with embedded systems, from the microcontroller in your washing machine to the complex avionics controlling a jet. These intricate systems, a marriage of hardware and software, are designed for specific tasks, often with real-time constraints and limited resources. While their ubiquity is undeniable, so too is the inevitability of their failure. When an embedded system falters, particularly in critical applications, the ability to diagnose and rectify the issue becomes paramount. This is where the “art” of reverse engineering a failing embedded system truly shines – a meticulous blend of detective work, technical prowess, and creative problem-solving.

This article delves into the multifaceted process of reverse engineering a failing embedded system, offering an in-depth guide for embedded engineers. We will explore the methodologies, tools, and mindset required to unravel the mysteries of a malfunctioning device, identify the root cause of its failure, and ultimately, pave the way for its repair or improvement.

The Inevitable: Why Embedded Systems Fail

Before embarking on the reverse engineering journey, it’s crucial to understand the common culprits behind embedded system failures. These can broadly be categorized into:

- Hardware Failures: This encompasses a vast array of issues, including component degradation (capacitors, resistors), solder joint fatigue, power supply instability, Electrostatic Discharge (ESD) damage, manufacturing defects, and even environmental factors like extreme temperature or humidity.

- Software Bugs: From logical errors and race conditions to memory leaks, stack overflows, and incorrect interrupt handling, software bugs are a pervasive cause of failure, often manifesting subtly and inconsistently.

- Firmware Corruption: Errors during firmware updates, power loss during writes, or malicious attacks can lead to corrupted firmware, rendering the device inoperable or erratic.

- Intermittent Faults: These are perhaps the most frustrating, as they occur sporadically, making diagnosis difficult. They can stem from marginal timing issues, poor signal integrity, or environmental factors that intermittently push the system beyond its operating limits.

- Design Flaws: Sometimes, the system’s design itself is the root cause, leading to limitations that become apparent only under specific operating conditions or after prolonged use. This could involve inadequate power filtering, insufficient thermal management, or a lack of robust error handling.

- External Factors: Electromagnetic Interference (EMI), power surges, or even deliberate tampering can induce failures in an otherwise healthy system.

Understanding these potential failure modes provides a valuable framework for approaching the reverse engineering process.

The Initial Assessment: Information Gathering and Non-Invasive Techniques

The journey begins with a thorough initial assessment. The goal here is to gather as much information as possible about the failing system without making any irreversible changes.

- Symptom Analysis: Meticulously document the failure symptoms. Is it a complete shutdown? Intermittent freezing? Incorrect output? Error codes? The more detailed the observation, the better. Try to reproduce the failure consistently. If it’s intermittent, attempt to identify triggers (e.g., specific inputs, temperature changes, time of day).

- External Inspection: Visually inspect the device for any obvious signs of damage:

- Physical damage: Cracks, dents, burn marks, swollen capacitors.

- Loose connections: Wires, connectors, or components that appear dislodged.

- Environmental indicators: Dust buildup, corrosion, liquid damage.

- Odor: A burning smell often indicates an electrical short or overheating component.

- Power Supply Verification: A stable and clean power supply is fundamental. Use a multimeter or oscilloscope to verify the input voltage and check for ripple. Fluctuations or noise in the power supply can cause unpredictable behavior.

- Connectivity Checks: If applicable, verify network connectivity (Ethernet, Wi-Fi, Bluetooth) and serial communication. Use network sniffers or serial port monitors to capture data and identify communication errors.

- Documentation Review (If Available): While reverse engineering often implies a lack of documentation, sometimes partial schematics, datasheets for specific components, or even user manuals can provide invaluable clues about the system’s intended operation and pinouts.

- Basic Diagnostic Tools:

- Multimeter: For checking continuity, voltage levels, and resistance.

- Logic Analyzer: To capture digital signals and observe timing relationships. This is incredibly useful for understanding communication protocols (I2C, SPI, UART) and verifying control signals.

- Oscilloscope: For analyzing analog signals, power supply ripple, and signal integrity issues. High-bandwidth oscilloscopes are essential for high-speed digital signals.

- Thermal Camera: To identify hot spots, which can indicate overheating components, shorts, or excessive current draw.

At this stage, the aim is to narrow down the potential problem areas. Is it a power issue? A communication breakdown? A specific component failing?

Deeper Dive: Invasive Techniques and Reverse Engineering the Hardware

Once non-invasive methods have exhausted their utility, it’s time to delve deeper into the hardware. This often involves carefully disassembling the device and meticulously examining its internal components.

- Component Identification:

- Microcontrollers/Microprocessors: Identify the main processing unit. Note down its part number. This is crucial for finding datasheets, programming guides, and potentially JTAG/SWD pinouts.

- Memory ICs: Identify RAM, Flash, EEPROM chips. These store firmware and data.

- Peripherals: Identify sensors, actuators, communication transceivers, power management ICs, and other specialized chips.

- Passive Components: Resistors, capacitors, inductors. While often overlooked, their failure can have significant impact.

- Tracing Traces and Schematics Reconstruction: This is the heart of hardware reverse engineering.

- Visual Tracing: Use a magnifying glass or microscope to follow traces on the PCB. This helps in understanding how components are interconnected.

- Continuity Testing: Use a multimeter in continuity mode to confirm connections between pins of ICs and other components.

- Layer Peeling (Advanced): For multi-layered PCBs, specialized techniques like careful grinding or chemical etching might be necessary to expose inner layers.

- Creating a Schematic: As you trace, start documenting your findings by sketching out a schematic. Tools like KiCad or Eagle can be used to create digital schematics, which can be invaluable for understanding the circuit’s logic. Pay close attention to power lines, ground planes, and signal paths.

- Bus Analysis: Identify and analyze critical buses like the data bus, address bus, and control bus if present. A logic analyzer can be invaluable here for observing bus activity and identifying unusual patterns or lack thereof.

- Power Delivery Network (PDN) Analysis: Even a minor issue in the PDN can cause widespread problems.

- Voltage Rails: Verify all voltage rails are at their specified levels and are stable.

- Decoupling Capacitors: Check the integrity of decoupling capacitors near ICs. Their failure can lead to voltage dips and noise, causing erratic behavior.

- Power Regulators: Ensure power regulators are functioning correctly and providing stable output.

- Component Testing and Replacement:

- In-Circuit Testing (Limited): For certain passive components (resistors, capacitors), some basic in-circuit testing can be performed using a multimeter.

- Out-of-Circuit Testing: Desolder suspect components and test them individually using appropriate equipment (e.g., component tester, LCR meter).

- Component Swapping: If you suspect a particular component, and have a known good replacement, try swapping it out to see if the problem resolves. This is often a last resort due to the risk of damaging the PCB.

Unveiling the Software: Firmware Extraction and Analysis

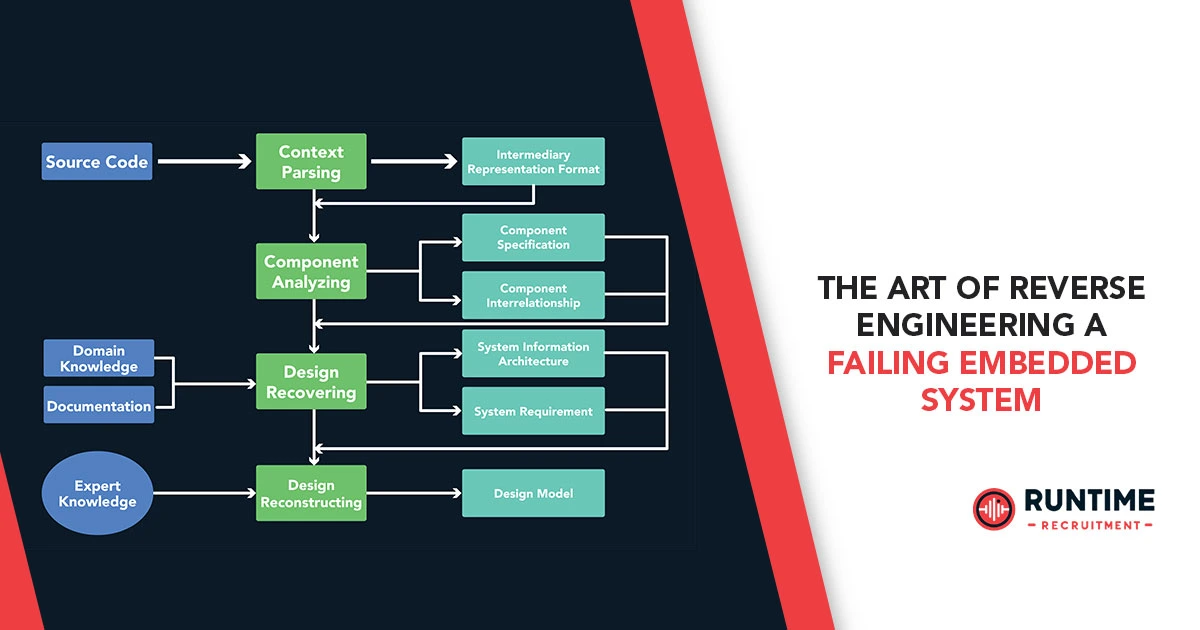

Understanding the hardware is only half the battle. The software, or firmware, dictates the system’s behavior. Extracting and analyzing it is often a critical step.

- Firmware Extraction Methods:

- JTAG/SWD Debug Ports: If debug ports (Joint Test Action Group/Serial Wire Debug) are exposed and active, this is the most straightforward method. Debuggers like OpenOCD with a compatible JTAG/SWD adapter (e.g., ST-Link, J-Link) can often read the entire flash memory.

- Serial Bootloaders: Some microcontrollers have built-in serial bootloaders that can be activated by holding specific pins high/low during power-up. This allows firmware download via UART.

- Memory Chip Desoldering: If no debug or bootloader access is available, the memory chip (e.g., NOR flash, NAND flash, EEPROM) can be desoldered and its contents read using a universal programmer. This requires careful desoldering techniques and an understanding of the memory chip’s pinout and programming protocol.

- Voltage Glitching/Fault Injection: More advanced and risky techniques might involve voltage glitching or fault injection to bypass read protection mechanisms. This requires specialized equipment and expertise.

- Firmware Analysis: Once extracted, the firmware is typically a raw binary file.

- Disassembly and Decompilation:

- Disassemblers: Tools like IDA Pro, Ghidra, or Radare2 can convert the binary into assembly language. This allows you to understand the program’s flow, identify functions, and analyze individual instructions.

- Decompilers: While not perfect, decompilers (often integrated into tools like Ghidra) attempt to translate assembly back into higher-level code (e.g., C). This significantly aids in understanding the program’s logic.

- String Search: Search for human-readable strings within the firmware. These can reveal error messages, configuration parameters, URLs, or function names, providing invaluable context.

- Function Identification: Identify critical functions, such as initialization routines, interrupt service routines (ISRs), communication handlers, and main loops.

- Vulnerability Analysis: Look for known vulnerabilities in the microcontroller’s architecture or common coding errors that could lead to system failure.

- Diffing Firmware Versions: If you have access to both a working and a failing firmware version, a binary diffing tool can highlight changes, potentially pinpointing the introduction of a bug.

- Disassembly and Decompilation:

- Runtime Analysis and Debugging:

- In-Circuit Debugging: If JTAG/SWD is active, connect a debugger and step through the code. This allows you to observe variable values, register states, and execution flow in real-time, making it possible to pinpoint exactly where the software is failing.

- Logging and Tracing: If the system has any built-in logging capabilities (e.g., UART output, flash logging), enable them to capture runtime information.

- Logic Analyzer with Protocol Decoding: For communication-related failures, a logic analyzer with protocol decoding capabilities can capture and interpret bus traffic, revealing incorrect data or timing issues.

The Detective’s Mindset: Problem Solving and Hypothesis Testing

Reverse engineering a failing embedded system is less about following a rigid checklist and more about embracing a detective’s mindset.

- Formulate Hypotheses: Based on your observations and analysis, propose potential causes for the failure. “The system is crashing because of a power supply brownout during a specific operation.” “The communication failure is due to incorrect baud rate configuration in the firmware.”

- Design Experiments to Test Hypotheses: Rigorously test each hypothesis. Can you intentionally induce the power brownout? Can you modify the firmware to change the baud rate and see if communication is restored?

- Elimination and Refinement: As you test, eliminate hypotheses that are disproven and refine those that seem plausible. This iterative process of observation, hypothesis, experimentation, and refinement is key.

- Think Outside the Box: Sometimes, the problem isn’t obvious. Consider obscure failure modes, environmental factors, or even interactions with other systems.

- Patience and Perseverance: This process can be time-consuming and frustrating. Be prepared for dead ends and false starts. Perseverance is a vital trait for any reverse engineer.

Case Studies and Real-World Scenarios

Consider a common scenario: a consumer electronics device that randomly freezes.

- Initial Assessment: Symptoms are random freezes. No obvious physical damage.

- Non-Invasive: Power supply appears stable. No external communication issues.

- Hardware Reverse Engineering: Disassemble. Identify microcontroller, RAM, and flash. Notice a slightly bulging capacitor near the power input. Trace the power delivery network.

- Hypothesis 1: The bulging capacitor is failing, leading to power supply instability, causing the random freezes.

- Experiment 1: Desolder the capacitor and test its capacitance. It’s significantly lower than specified. Replace it with a new one.

- Result: The device no longer freezes. Root Cause Identified: Hardware failure (degraded capacitor).

Another scenario: An industrial sensor unit is sending incorrect data intermittently.

- Initial Assessment: Symptoms are incorrect readings, not consistently wrong but sporadically.

- Non-Invasive: Power supply stable. Communication protocol verified, but data values are wrong.

- Hardware Reverse Engineering: Identify the sensor IC and its connection to the microcontroller.

- Firmware Extraction & Analysis: Extract firmware. Disassemble relevant sensor reading functions.

- Hypothesis 1: A software bug in the sensor data processing routine is causing incorrect calculations under specific conditions.

- Hypothesis 2: The sensor itself is faulty intermittently.

- Experiment 1 (Software): Using a debugger, step through the sensor reading function while observing real-time sensor data input. Identify a floating-point calculation error that occurs only with specific input ranges.

- Experiment 2 (Hardware – if software fix fails): If the software fix doesn’t work, consider swapping the sensor IC.

- Result: Software bug identified and patched. Root Cause Identified: Software bug (calculation error).

Tools of the Trade (Beyond the Basics)

Beyond the fundamental tools, a more advanced arsenal can significantly enhance reverse engineering capabilities:

- BGA Rework Station: For desoldering and reballing Ball Grid Array (BGA) components, which are common in modern embedded systems.

- Microscope (Stereo and Digital): Essential for inspecting fine traces, solder joints, and component markings.

- Hot Air Rework Station: For removing and replacing surface-mount components.

- JTAG/SWD Programmers/Debuggers: As mentioned, tools like SEGGER J-Link, ST-Link, or Bus Pirate.

- Universal IC Programmers: For reading and writing to various memory chips.

- RF Spectrum Analyzer: For diagnosing wireless communication issues.

- Environmental Chambers: For testing devices under varying temperature and humidity conditions to reproduce intermittent faults.

- Specialized Software: Logic analyzer software with protocol decoders, oscilloscope software for advanced analysis, PCB design software (KiCad, Altium Designer) for schematic capture and layout viewing, and various data analysis tools.

Ethical Considerations and Best Practices

While reverse engineering is a powerful diagnostic tool, it’s crucial to acknowledge ethical and legal considerations.

- Intellectual Property: Be mindful of intellectual property rights. Reverse engineering for personal repair or learning is generally acceptable, but replicating or distributing proprietary designs without permission is illegal.

- Warranty: Opening a device will almost certainly void its warranty.

- Safety: Always prioritize safety. Work in a well-ventilated area, use appropriate ESD precautions, and be aware of high voltages.

- Documentation: Meticulously document every step of your process, including observations, hypotheses, experiments, and results. This not only helps in the current task but also builds a valuable knowledge base for future endeavors.

- Cleanliness: Maintain a clean workspace to avoid losing small components or introducing foreign contaminants.

Conclusion: The Evolving Art

The art of reverse engineering a failing embedded system is a dynamic and continuously evolving field. As embedded systems become more complex, miniaturized, and integrated, the challenges for reverse engineers grow. The increasing prevalence of System-on-Chips (SoCs) and highly integrated components means that traditional component-level troubleshooting might become less feasible, pushing engineers towards more firmware-centric analysis and even advanced techniques like X-ray imaging and delayering.

However, the core principles remain constant: meticulous observation, systematic analysis, creative problem-solving, and an insatiable curiosity to understand how things work (and why they don’t). For embedded engineers, mastering this art is not just about fixing broken devices; it’s about gaining a deeper understanding of system design, identifying weaknesses, and ultimately contributing to the creation of more robust and reliable embedded systems in the future. It’s a testament to the engineer’s commitment to unraveling complexity and bringing order back to the chaotic world of malfunctioning electronics.