The Internet of Things (IoT) is no longer a futuristic concept; it’s a pervasive reality. From smart homes to industrial control systems, billions of interconnected devices are generating unprecedented volumes of data. At the heart of most IoT applications are sensors, the unsung heroes that translate the physical world into digital insights. However, the true value of this data hinges on its accuracy, and that’s where sensor calibration becomes paramount.

For embedded engineers navigating the complexities of large-scale IoT deployments, the traditional, manual approaches to calibration are simply unsustainable. This article delves into the critical need for automated sensor calibration techniques when dealing with millions of IoT devices, exploring various strategies and their practical implications.

The Unavoidable Imperative: Why Calibration Matters in IoT

Imagine a smart city system monitoring air quality, traffic flow, or structural integrity. If the environmental sensors providing this data are inaccurate, the resulting decisions—whether to reroute traffic, issue pollution warnings, or dispatch maintenance crews—will be flawed, potentially leading to significant economic losses, safety hazards, or a complete loss of trust in the system.

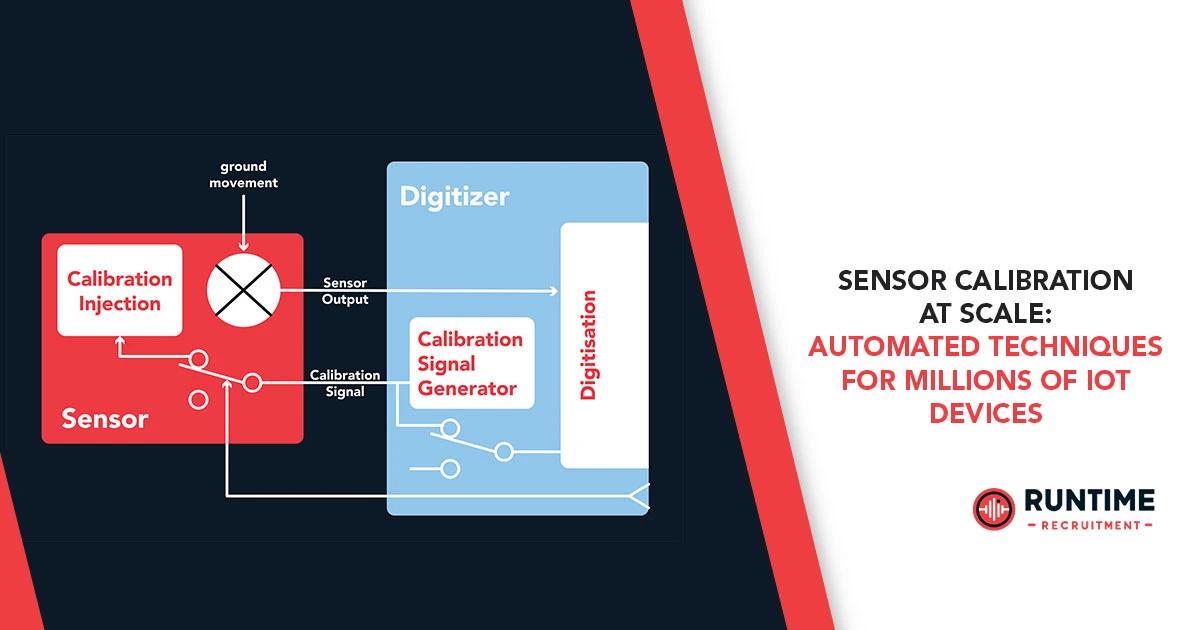

Calibration is the process of adjusting a sensor’s output to match a known standard. It corrects for manufacturing variances, environmental influences (like temperature and humidity), and sensor drift over time. Without proper calibration, even the most sophisticated analytics algorithms will be fed garbage, leading to the infamous “garbage in, garbage out” scenario.

In small-scale deployments, an engineer might manually calibrate each sensor or batch of sensors. This involves comparing the sensor’s reading to a highly accurate reference instrument and adjusting the sensor’s internal parameters or applying a compensation algorithm. While feasible for a few dozen or even a few hundred devices, this approach breaks down completely when you’re deploying hundreds of thousands or millions of devices across vast geographical areas. The cost, time, and logistical overhead become prohibitive.

The Scale Challenge: Why Manual Calibration Fails

Consider the lifecycle of an IoT device:

- Manufacturing: Sensors have inherent variations from the production line.

- Deployment: Devices are installed in diverse environments, each with unique operating conditions.

- Operation: Sensors drift over time due to aging, exposure to harsh conditions, or mechanical stress.

- Maintenance: Recalibration or replacement becomes necessary.

For a million devices, manually addressing these calibration needs at each stage is a monumental task.

- Cost: Labor, equipment, and transportation costs skyrocket.

- Time: The sheer volume of devices makes individual calibration an endless process.

- Consistency: Manual processes are prone to human error, leading to inconsistent calibration quality.

- Scalability: As the deployment grows, the problem compounds linearly, or even exponentially, if not addressed proactively.

- Accessibility: Many IoT devices are deployed in remote, hazardous, or difficult-to-access locations, making on-site manual calibration impractical or impossible.

This brings us to the core challenge: how can we ensure the accuracy of millions of sensors throughout their operational lifespan without breaking the bank or sacrificing reliability? The answer lies in automation.

Automated Calibration Techniques: A Multi-Pronged Approach

Automated sensor calibration isn’t a single solution but rather a suite of techniques that can be applied at different stages of the IoT device lifecycle. These techniques often leverage software, machine learning, and clever hardware design.

1. Factory-Floor Calibration Automation

The first opportunity for automation is during manufacturing. Instead of manual adjustments, robotic systems and automated test jigs can calibrate sensors quickly and consistently.

- Automated Test Benches: Robotic arms can precisely position sensors in front of reference standards (e.g., a calibrated temperature bath, a known pressure source, or a light intensity meter). Software then records the sensor’s output, compares it to the reference, and automatically computes calibration coefficients. These coefficients are then programmed into the device’s firmware.

- Batch Calibration: For certain sensor types, it’s possible to calibrate batches of sensors simultaneously, further accelerating the process.

- End-of-Line Testing: Comprehensive automated testing at the end of the production line ensures that each device meets its calibration specifications before shipment.

This upfront automation significantly reduces the initial burden of calibration and ensures a baseline level of accuracy for all devices.

2. Self-Calibration and Self-Correction Mechanisms

For devices already in the field, the ability to self-calibrate or self-correct is invaluable. This reduces the need for physical intervention.

- Built-in Reference Sensors: Some advanced sensors incorporate a highly stable, internal reference element. The primary sensing element can periodically compare its readings against this internal reference and adjust its output accordingly. For example, some gas sensors have an internal heater that can burn off contaminants, returning the sensor to a baseline.

- Redundant Sensors: Deploying multiple identical sensors in close proximity allows for cross-validation. If one sensor drifts, its reading will deviate from the others, signaling a potential issue. This can trigger a self-correction mechanism where the device averages the readings of the stable sensors or attempts to recalibrate the outlier.

- Environmental Compensation: Modern sensors often include built-in temperature and humidity sensors. The main sensor’s output can be compensated in real-time based on these environmental readings, as many sensing principles are affected by ambient conditions. This is a form of continuous, automated adjustment.

- Periodic Zero/Span Checks: For sensors that measure relative values (e.g., pressure differentials, gas concentrations), it’s often possible to periodically expose the sensor to a known zero-level input (e.g., ambient air for a gas sensor, or atmospheric pressure for a differential pressure sensor) or a known span-level input using an internal calibration gas cylinder or a controlled mechanism. The sensor can then adjust its offset and gain.

3. Over-the-Air (OTA) Calibration Updates

One of the most powerful automated techniques for deployed devices is the ability to push calibration updates wirelessly.

- Firmware Updates: Calibration coefficients are often stored in the device’s firmware. When new, more accurate calibration data or improved compensation algorithms become available, they can be pushed to devices as firmware updates, similar to how smartphones receive software updates.

- Cloud-Based Calibration Management: A central cloud platform can store calibration profiles for all devices. When a device requires recalibration, the cloud system can generate new coefficients based on various factors (e.g., operating history, environmental data, predictive models) and push these parameters to the device.

- Adaptive Calibration Models: As more data is collected from a device, machine learning models in the cloud can refine the calibration coefficients. For example, if a temperature sensor consistently reads slightly high in a certain temperature range, the cloud model can learn this bias and send an updated compensation curve to the device.

OTA updates are critical for maintaining accuracy over the long term, especially for devices with long lifecycles that are difficult to access physically.

4. Machine Learning and Data-Driven Calibration

This is perhaps the most exciting and rapidly evolving area of automated calibration. Instead of relying solely on physical references, machine learning models can infer and correct sensor drift and errors from the data itself.

- Fleet Learning: By analyzing data from an entire fleet of similar sensors, machine learning algorithms can identify common drift patterns or biases. If a specific batch of sensors consistently shows a particular deviation under certain conditions, a fleet-wide compensation model can be developed and applied.

- Anomaly Detection for Drift: ML models can continuously monitor sensor data for anomalies that indicate drift. For example, if a sensor’s readings suddenly diverge from its historical pattern or from neighboring sensors in a way that can’t be explained by environmental changes, it can flag the sensor for recalibration.

- Virtual Sensors: In some cases, it’s possible to create “virtual sensors” by using data from other, more reliable sensors or environmental factors to predict the output of a less reliable or uncalibrated sensor. For example, if you have calibrated temperature sensors and uncalibrated humidity sensors in the same environment, an ML model could learn the relationship and infer the correct humidity values.

- Predictive Maintenance and Calibration: Machine learning can predict when a sensor is likely to drift out of calibration based on its operating history, environmental exposure, and typical failure modes. This allows for proactive (automated) recalibration or scheduled maintenance, minimizing downtime and ensuring continuous data quality.

- “Golden Sensor” Referencing (Self-Organizing Sensor Networks): In a network of identical sensors, one or a few highly stable “golden sensors” can be strategically placed and periodically checked against an external reference. The other sensors in the network can then use these golden sensors as a local reference, continuously adjusting their own readings to match the golden sensor’s output. This creates a self-organizing and self-calibrating network.

Implementation Considerations for Embedded Engineers

Implementing automated calibration at scale requires careful planning and execution, with embedded engineers playing a pivotal role.

- Hardware Design for Calibrability:

- Accessible Calibration Ports: Even if primarily automated, physical calibration ports are useful for initial setup or troubleshooting.

- On-chip Memory for Coefficients: Ensure sufficient non-volatile memory (e.g., EEPROM, Flash) to store calibration coefficients.

- Processing Power: Microcontrollers need enough processing power to execute compensation algorithms.

- Stable References: Design for stable voltage references and clock sources if the sensor relies on these.

- Firmware Architecture:

- Modular Calibration Code: Separate calibration routines from the main application logic for easier updates.

- Robust Update Mechanisms: Implement secure and reliable OTA update protocols.

- Error Handling: Design for graceful degradation or failure modes if calibration data is corrupted or updates fail.

- Diagnostics: Include diagnostic capabilities to report calibration status and sensor health.

- Data Management and Cloud Infrastructure:

- Calibration Database: A centralized database to store unique calibration profiles for each device.

- Secure Communication: Encrypted channels for transmitting calibration data and updates.

- Scalable Cloud Processing: Infrastructure capable of handling large volumes of sensor data for ML-driven calibration.

- Version Control: Manage different versions of calibration algorithms and coefficients.

- Testing and Validation:

- Automated Testing Pipelines: Rigorous testing of calibration algorithms and OTA update mechanisms.

- Reference Standards: Maintain traceable reference standards for validating automated calibration results.

- Field Trials: Pilot deployments to test automated calibration in real-world conditions before full-scale rollout.

- Security:

- Tamper Detection: Protect calibration parameters from unauthorized modification, as compromised calibration can lead to false data and system vulnerabilities.

- Secure Boot: Ensure that only authenticated firmware, including calibration updates, can be loaded onto the device.

Challenges and Future Directions

While automated calibration offers immense benefits, it’s not without its challenges.

- Computational Overhead: Complex ML algorithms can demand significant processing power, which can be a constraint for resource-limited edge devices. Edge AI accelerators or offloading to the cloud can mitigate this.

- Data Volume and Quality: ML-driven calibration requires vast amounts of high-quality, labeled data for training.

- Initial Setup Cost: Developing and deploying automated calibration systems can have a high upfront cost, though this is quickly offset by savings at scale.

- Security Vulnerabilities: OTA updates and cloud-based systems introduce new attack vectors that must be rigorously secured.

- Sensor Heterogeneity: Calibrating a diverse range of sensor types with varying operating principles adds complexity.

Looking ahead, we can expect:

- Increased Edge AI: More powerful embedded processors will enable on-device machine learning for self-calibration without constant cloud connectivity.

- Federated Learning for Calibration: Collaborative learning across distributed devices without sharing raw data, addressing privacy concerns.

- Digital Twins: Creating precise digital replicas of physical sensors and their environments to simulate and optimize calibration strategies.

- Standardization: Greater standardization in calibration interfaces and protocols across different sensor manufacturers.

- Explainable AI (XAI): Making ML-driven calibration processes more transparent and understandable to engineers, building trust in autonomous systems.

Conclusion

For embedded engineers operating in the era of pervasive IoT, automated sensor calibration is not a luxury but a fundamental necessity. The ability to maintain data accuracy across millions of devices, often in diverse and challenging environments, underpins the reliability and trustworthiness of entire IoT ecosystems. By embracing factory automation, self-correction mechanisms, OTA updates, and especially the transformative power of machine learning, engineers can design and deploy scalable IoT solutions that deliver accurate, actionable insights, driving innovation and efficiency across industries. The future of IoT is precise, and precision at scale is achieved through intelligent automation.

Ready to shape the future of IoT? Connect with RunTime Recruitment to find your next challenge in embedded systems and sensor technology.