Introduction

Embedded systems are at the heart of modern industrial automation, IoT devices, and smart infrastructure. One of the most critical challenges in these systems is ensuring reliability through predictive maintenance (PdM). Traditional maintenance approaches rely on scheduled inspections or reactive repairs, which can be inefficient and costly.

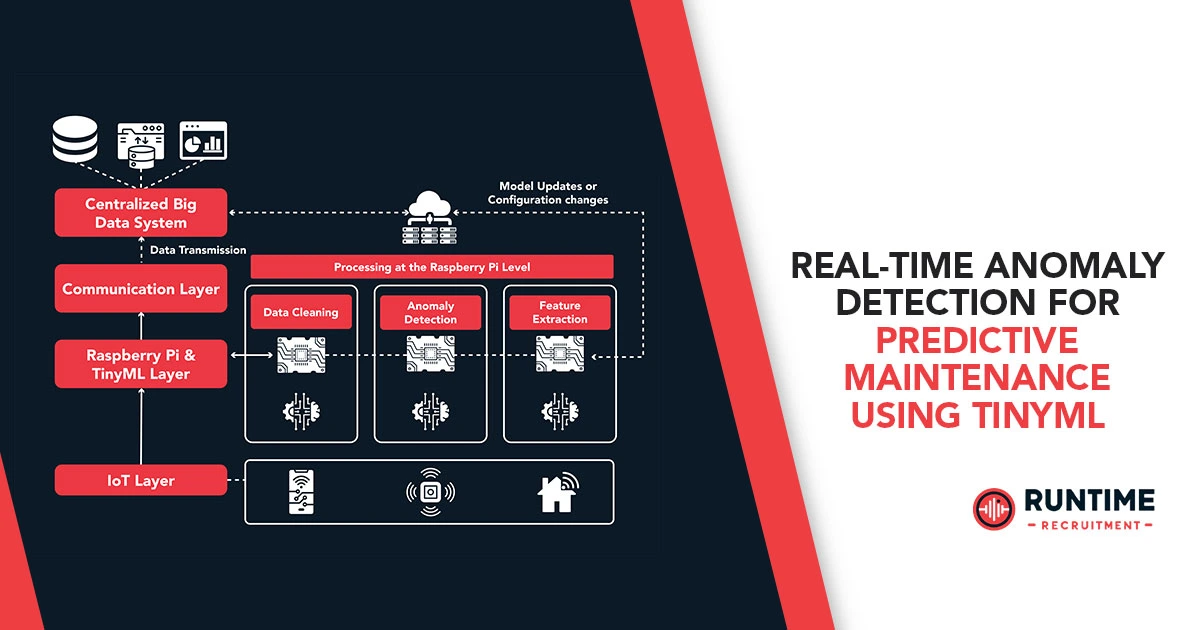

Enter TinyML—a fusion of embedded systems and machine learning (ML) that enables real-time anomaly detection directly on microcontrollers (MCUs). By deploying lightweight ML models on edge devices, engineers can detect faults early, reduce downtime, and extend equipment lifespan.

This article explores how TinyML enables real-time anomaly detection for predictive maintenance, covering:

- The Need for Anomaly Detection in Embedded Systems

- Challenges in Traditional Predictive Maintenance

- How TinyML Enables On-Device Anomaly Detection

- Key Algorithms for Real-Time Anomaly Detection

- Implementing TinyML for Predictive Maintenance

- Case Studies and Industry Applications

- Future Trends and Challenges

1. The Need for Anomaly Detection in Embedded Systems

Industrial machines, automotive systems, and IoT sensors generate vast amounts of operational data. Anomalies—unexpected deviations from normal behavior—can indicate impending failures. Detecting these anomalies in real-time is crucial for:

- Preventing catastrophic failures (e.g., motor burnout, bearing wear).

- Reducing unplanned downtime (saving millions in industrial settings).

- Optimizing maintenance schedules (moving from reactive to predictive).

However, sending all sensor data to the cloud for analysis introduces latency, bandwidth costs, and privacy concerns. This is where TinyML shines—by processing data locally on low-power MCUs.

2. Challenges in Traditional Predictive Maintenance

Traditional PdM approaches include:

- Rule-based thresholding (simple but prone to false alarms).

- Cloud-based ML models (high latency, not real-time).

- Vibration analysis & spectral techniques (computationally heavy).

Limitations:

- High power consumption for continuous monitoring.

- Dependency on cloud connectivity (not feasible in remote deployments).

- Limited by MCU compute constraints (most ML models are too large).

TinyML addresses these by running optimized ML models directly on microcontrollers.

3. How TinyML Enables On-Device Anomaly Detection

TinyML leverages model compression, quantization, and efficient neural architectures to fit ML models into resource-constrained devices (e.g., ARM Cortex-M, ESP32, Raspberry Pi Pico).

Key Techniques:

- Quantization: Reducing model weights from 32-bit floats to 8-bit integers (smaller memory footprint).

- Pruning: Removing redundant neurons to shrink model size.

- Knowledge Distillation: Training a smaller “student” model to mimic a larger one.

- Edge-optimized architectures: Using TinyML frameworks like TensorFlow Lite for Microcontrollers, Edge Impulse, and STM32Cube.AI.

Example Workflow:

- Data Collection: Vibration, temperature, current sensors.

- Feature Extraction: FFT, statistical features (mean, variance).

- Model Training: Train a lightweight autoencoder or Random Forest.

- Deployment: Flash model to an MCU for real-time inference.

4. Key Algorithms for Real-Time Anomaly Detection

Not all ML models are suitable for TinyML. The best candidates are:

A. Autoencoders (Neural Networks)

- How it works: Compresses input data into a latent space and reconstructs it. Anomalies have high reconstruction errors.

- Pros: Effective for complex patterns.

- Cons: Requires careful tuning for MCUs.

B. One-Class SVM

- How it works: Learns a boundary around normal data; outliers are anomalies.

- Pros: Works well with small datasets.

- Cons: Computationally heavy for high dimensions.

C. Isolation Forest

- How it works: Randomly partitions data; anomalies are isolated faster.

- Pros: Low memory usage, fast inference.

- Cons: Less accurate for high-frequency sensor data.

D. Statistical Methods (Z-Score, Moving Average)

- How it works: Flags data points outside ±3σ from the mean.

- Pros: Simple, ultra-lightweight.

- Cons: Poor for dynamic environments.

Recommendation: For TinyML, quantized autoencoders or Isolation Forests offer the best balance.

5. Implementing TinyML for Predictive Maintenance

Step 1: Hardware Selection

- MCU: STM32H7 (with FPU), ESP32, Nordic nRF52840.

- Sensors: Accelerometers (ADXL345), current sensors (ACS712), thermocouples.

Step 2: Data Collection & Preprocessing

- Sample at 1-10kHz for vibration, 1Hz for temperature.

- Apply noise filtering (median, Butterworth).

Step 3: Model Training (Edge Impulse Example)

- Upload sensor data to Edge Impulse Studio.

- Extract features (RMS, spectral kurtosis).

- Train a TinyML model (e.g., 20KB TFLite model).

- Deploy as a C++ library for your MCU.

Step 4: Real-Time Inference

- Run model in a 10ms loop for continuous monitoring.

- Trigger alerts via UART, LoRa, or BLE if anomalies exceed a threshold.

6. Case Studies & Industry Applications

A. Predictive Maintenance in Industrial Motors

- Problem: Bearing failures cause costly downtime.

- Solution: STM32 + TinyML detects abnormal vibrations 48hrs before failure.

B. Smart HVAC Systems

- Problem: Compressor failures in cooling systems.

- Solution: ESP32 monitors current spikes using an Isolation Forest.

C. Automotive Predictive Maintenance

- Problem: Early detection of engine misfires.

- Solution: TinyML on an automotive-grade MCU analyzes OBD-II data.

7. Future Trends & Challenges

Opportunities:

- Federated Learning: Collaborative model updates across devices.

- Neuromorphic Chips: Event-based processing for ultra-low power.

- TinyML-as-a-Service: Cloud platforms for edge model management.

Challenges:

- Limited MCU memory (models must stay under 100KB).

- Labeling anomalies is hard (few real-world failure datasets).

- Model drift (requiring periodic retraining).

Conclusion

TinyML is revolutionizing predictive maintenance by enabling real-time, on-device anomaly detection without cloud dependency. Embedded engineers can leverage quantized neural networks, efficient feature extraction, and ultra-low-power MCUs to build smarter, self-monitoring systems.

As TinyML frameworks mature, we’ll see wider adoption in industrial IoT, automotive, and smart infrastructure—ushering in an era of truly autonomous predictive maintenance.