Digital twins have become a hot topic in the tech sphere, promising to revolutionize how we design, operate, and maintain physical assets. But beneath the buzzwords lies a powerful concept with real-world applications. This article dives deep into digital twin technology, exploring its inner workings, benefits, implementation strategies, and the challenges to overcome.

What is Digital Twin Technology?

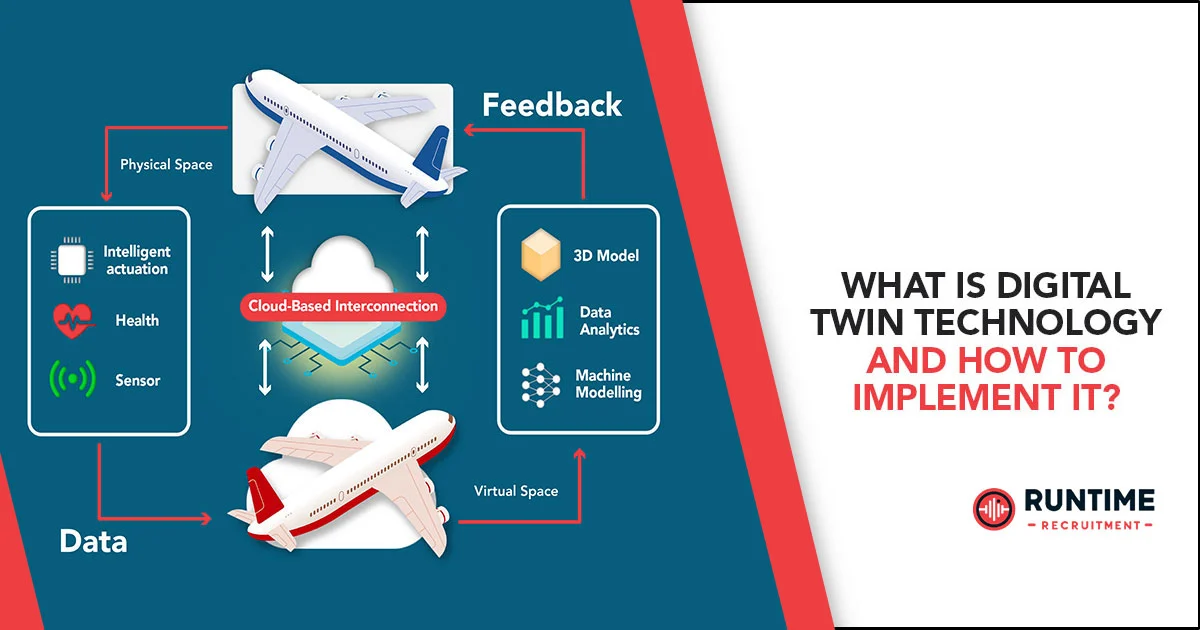

Imagine a virtual counterpart to a physical object, a machine, a process, or even an entire city. Constantly updated with real-time data, this digital replica mirrors its physical twin’s behavior and performance. That’s the essence of digital twin technology.

More than a simple 3D model, a digital twin is a dynamic software program that integrates various technologies:

- Internet of Things (IoT): Sensors embedded in the physical object continuously transmit data – temperature, pressure, vibration, etc. – feeding the digital model with real-world insights.

- Data Management and Analytics: This layer ingests sensor data, historical records, engineering specifications, and maintenance logs. Advanced analytics tools extract valuable insights and patterns from this data pool.

- Modeling and Simulation: The core of the digital twin is a simulation engine that uses the collected data to create a virtual representation of the physical system. This model can be used to predict future performance, optimize operations, and identify potential issues.

- Machine Learning (ML): As the digital twin accumulates data over time, ML algorithms can learn from it, making even more accurate predictions and enabling autonomous decision-making.

How Does Digital Twin Technology Work?

The functionality of a digital twin can be categorized by levels of sophistication:

- Descriptive: Provides a real-time view of the physical system’s current state.

- Informative: Offers historical data and insights into past performance.

- Predictive: Analyzes data to predict potential issues and recommend maintenance actions.

- Comprehensive: Integrates all prior levels, enabling proactive optimization and performance improvement.

- Autonomous: Utilizes ML to make automated decisions based on real-time data analysis.

Benefits of Digital Twins

The potential benefits of digital twins span across industries, offering a significant competitive edge. Here are some key advantages:

- Improved Performance: Digital twins enable continuous monitoring of performance metrics, allowing for real-time optimization of processes. This translates to increased efficiency, reduced downtime, and improved product quality.

- Predictive Capabilities: By analyzing historical data and current sensor readings, digital twins can predict equipment failures, enabling proactive maintenance strategies. This reduces the risk of unplanned downtime and costly repairs. [1]

- Remote Monitoring: Digital twins provide remote access to vital data and visualizations of the physical system. This allows for improved decision-making without requiring physical presence at the site.

- Enhanced Design and Development: Digital twins can be used to simulate product performance in a virtual environment before physical prototypes are built. This enables early identification of design flaws and facilitates faster development cycles. [2]

- Improved Training and Safety: Digital twins can be used to create realistic training simulations for operators, improving their understanding of complex systems and promoting safety protocols. [3]

Types of Digital Twins

Digital twins can be created for various components within a system, catering to specific needs. Here are some common types:

- Component Twins: Focus on a single component, such as a sensor or a motor, providing detailed insights into its health and performance.

- Asset Twins: Represent individual assets like a wind turbine or a production line, enabling condition monitoring and predictive maintenance.

- System Twins: Model entire systems, such as a power plant or a factory floor, facilitating system-wide optimization and performance analysis.

- Process Twins: Replicate specific processes like product assembly or supply chain logistics, allowing for process improvement and optimization.

When to Use Digital Twins

Digital twins are particularly valuable in scenarios involving complex systems, high-value assets, or processes with critical downtime risks. Industries like manufacturing, energy, aerospace, healthcare, and transportation can leverage digital twins to gain a significant operational advantage. [4]

How to Implement Digital Twin Technology

Implementing a successful digital twin solution requires a well-defined strategy and a collaborative approach. Here’s a breakdown of the key steps:

- Data Collection and Management: Identify the data points crucial for your digital twin, and establish a robust data collection infrastructure using IoT sensors and existing data sources. Ensure proper data governance and security protocols are in place.

- Building the Digital Model: Choose a modeling platform or develop a custom model that integrates with your data management system. Consider factors like scalability, interoperability with existing software, and ease of integration with future upgrades.

- Using the Digital Twin: Leverage the functionalities of your digital twin for various purposes. Utilize simulations to test scenarios, predict outcomes, and optimize operations. Leverage visualization tools for real-time monitoring and communication of key performance indicators (KPIs).

Challenges of Implementing Digital Twins

Despite the significant benefits, implementing digital twins presents several challenges:

- Data Integration and Management: Ensuring seamless data flow from various sources, including real-time sensor data, historical records, and engineering data, can be complex. Standardizing data formats and establishing robust data governance practices are crucial.

- Security Concerns: Protecting sensitive data collected from physical assets and the digital twin itself is paramount. Implementing robust cybersecurity measures is essential to prevent unauthorized access or data breaches. [5]

- Technical Expertise: Building and maintaining digital twins requires expertise in various areas, including data science, modeling and simulation, and IoT technology. Companies may need to invest in upskilling their workforce or partnering with digital twin solution providers.

- Cost Considerations: The cost of implementing and maintaining a digital twin solution can be significant, including hardware, software, data storage, and ongoing maintenance. However, the long-term benefits in terms of efficiency improvements and cost savings often outweigh the initial investment.

Additional Considerations

- Digital Twin Maturity: As mentioned earlier, digital twins can operate at various levels of sophistication. Companies can start with simpler implementations and gradually increase complexity as they gain experience and expertise.

- Scalability and Interoperability: Choose a digital twin solution that can scale to accommodate future growth and seamlessly integrate with existing enterprise systems.

- Change Management: Implementing digital twins often involves a cultural shift within an organization. Effective communication and training programs are essential to ensure user adoption and maximize the technology’s benefits.

Wrapping Up

Digital twin technology holds immense potential to transform how we design, operate, and maintain physical assets across industries. By overcoming implementation challenges and embracing a data-driven approach, companies can leverage digital twins to gain a significant competitive edge. With continuous advancements in technology and increasing adoption, digital twins are poised to become a fundamental building block for future intelligent systems.

Hire the Best Engineers with RunTime

At RunTime, we are dedicated to helping you find the best Engineering talent for your recruitment needs. Our team consists of engineers-turned-recruiters with an extensive network and a focus on quality. By partnering with us, you will have access to great engineering talent that drives innovation and excellence in your projects.

Discover how RunTime has helped 423+ tech companies find highly qualified and talented engineers to enhance their team’s capabilities and achieve strategic goals.

On the other hand, if you’re a control systems engineer looking for new opportunities, RunTime Recruitment’s job site is the perfect place to find job vacancies.