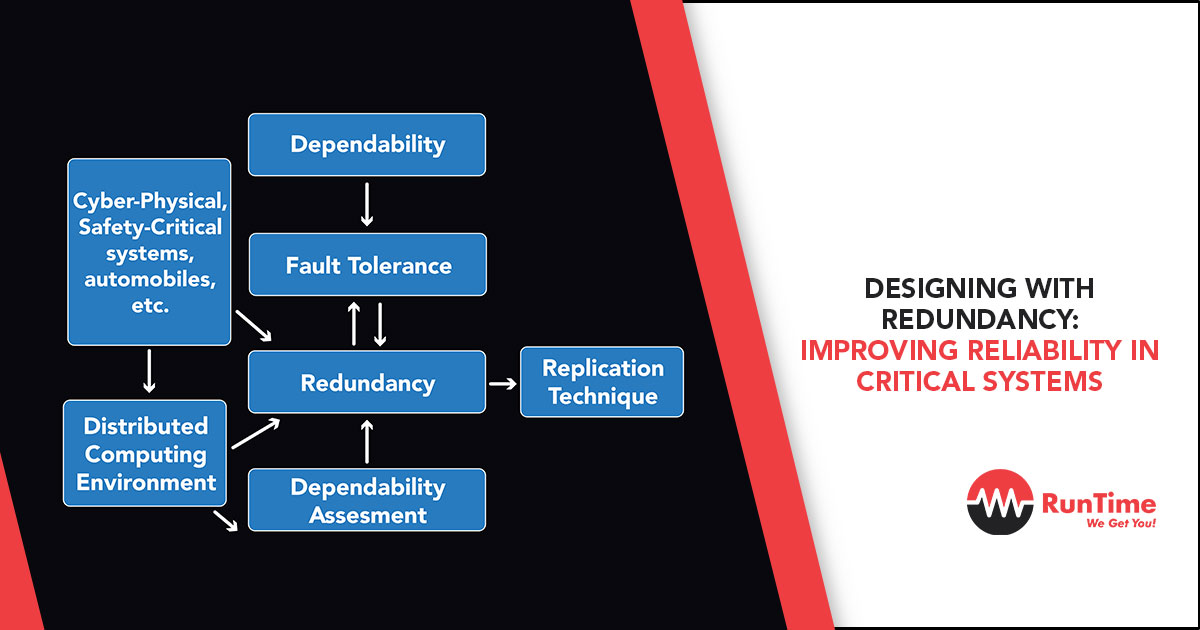

In the realm of embedded engineering, reliability is paramount, especially in critical systems where failures can lead to catastrophic consequences. From aerospace and automotive systems to medical devices and industrial automation, ensuring reliable operation is a fundamental design goal. Redundancy is one of the most effective strategies for achieving this reliability, providing a safeguard against component failures, software bugs, and unforeseen operational conditions.

This article delves into the concept of redundancy in embedded system design, exploring its types, benefits, challenges, and implementation strategies. By understanding and applying redundancy principles, embedded engineers can create systems that not only meet but exceed reliability requirements.

What is Redundancy in Embedded Systems?

Redundancy refers to the inclusion of additional resources, components, or systems that serve as backups to maintain functionality when a primary system fails. In embedded systems, redundancy can be implemented at various levels, including hardware, software, and data.

Why Redundancy Matters in Critical Systems

- Improved Fault Tolerance: Redundancy allows systems to continue operating even when some components fail.

- Enhanced Safety: Critical systems, such as those in medical devices or aircraft, require fail-safe mechanisms to protect human lives.

- Increased Availability: Redundant systems minimize downtime, ensuring continuous operation in industrial or service environments.

- Resilience to Environmental Factors: Redundancy mitigates risks associated with harsh operating conditions, such as temperature extremes or electromagnetic interference.

Types of Redundancy in Embedded Systems

Redundancy can be broadly classified into the following categories:

1. Hardware Redundancy

Involves duplicating hardware components to provide backup in case of failure.

Examples:

- Dual Power Supplies: Ensuring continuous operation even if one power supply fails.

- Redundant Sensors: Using multiple sensors to cross-verify critical measurements.

- Parallel Processing Units: Implementing multiple processors to execute the same task for fault tolerance.

Advantages:

- Provides immediate fallback in case of hardware failure.

- Can be implemented with minimal latency.

Challenges:

- Increased cost, size, and power consumption due to additional components.

- Potential for failure modes in redundant components (e.g., common-mode failures).

2. Software Redundancy

Involves adding redundancy in software to detect and recover from faults.

Examples:

- Watchdog Timers: Monitoring the system for software crashes or infinite loops.

- Checkpointing and Rollback: Saving system states periodically to recover from failures.

- Diverse Redundant Programming: Using different algorithms or implementations for the same task to mitigate software bugs.

Advantages:

- Minimal impact on hardware cost.

- Flexible and easily upgradable.

Challenges:

- Higher software complexity.

- Potential performance overhead due to additional checks.

3. Data Redundancy

Ensures the reliability of data storage and communication by duplicating or encoding data.

Examples:

- Error Detection and Correction (EDAC): Using parity bits or Hamming codes to detect and correct errors in memory or communication.

- RAID Configurations: Implementing redundancy in data storage systems to protect against disk failures.

- Data Replication: Maintaining multiple copies of critical data in different locations.

Advantages:

- Ensures data integrity and reliability.

- Often low-cost when implemented in software.

Challenges:

- Increased memory or storage requirements.

- Performance impact due to redundancy mechanisms.

4. Functional Redundancy

Involves implementing multiple independent systems to perform the same function.

Examples:

- Triple Modular Redundancy (TMR): Using three independent modules and a majority-voting mechanism to determine the correct output.

- Hot and Cold Standby Systems: Maintaining backup systems that can take over in case of a primary system failure.

Advantages:

- High fault tolerance.

- Effective for critical systems requiring continuous operation.

Challenges:

- High implementation cost and complexity.

- Synchronization overhead in real-time systems.

Best Practices for Designing with Redundancy

1. Identify Critical Components

Focus redundancy efforts on components that are most critical to system reliability. Use Failure Mode and Effects Analysis (FMEA) to identify potential failure points.

Example:

In an automotive braking system, redundant sensors and actuators are essential to ensure safety-critical operation.

2. Choose the Right Level of Redundancy

Balance redundancy with cost, size, and power constraints. Over-engineering redundancy can lead to diminishing returns.

Example:

For a low-cost IoT device, software-based watchdog timers may suffice, whereas a spacecraft may require full hardware redundancy.

3. Use Independent Redundant Paths

Ensure redundant components or systems are as independent as possible to avoid common-mode failures.

Example:

For redundant power supplies, use separate power sources to prevent simultaneous failure due to a single upstream issue.

4. Implement Fault Detection and Isolation

Redundancy alone isn’t sufficient without mechanisms to detect and isolate faults. Use error detection codes, diagnostic software, or self-test routines.

Example:

In a redundant sensor system, periodically compare sensor readings to identify and isolate faulty sensors.

5. Design for Graceful Degradation

Allow the system to operate at reduced functionality when redundancy is partially compromised.

Example:

An aircraft flight control system should maintain basic control capabilities even if some redundant components fail.

6. Test for Redundancy Effectiveness

Thoroughly test redundant systems under simulated fault conditions to ensure they operate as intended.

Example:

For a redundant storage system, simulate disk failures and verify data recovery processes.

Case Studies: Redundancy in Action

1. Spacecraft Control Systems

Spacecraft systems often use Triple Modular Redundancy (TMR) to ensure reliability in harsh environments. For example:

- Three processors execute the same instructions, and a majority-voting mechanism determines the correct output.

- Redundant power supplies and communication links mitigate the risk of total system failure.

2. Automotive Safety Systems

Modern vehicles rely on redundant sensors and controllers for safety-critical systems like anti-lock braking and airbag deployment. Examples include:

- Dual-channel accelerometers to ensure reliable crash detection.

- Redundant CAN bus communication to prevent data loss due to network faults.

3. Data Centers

Data centers implement redundancy through RAID storage systems, redundant power supplies, and backup generators to ensure continuous operation. Key features include:

- Data replication across geographically dispersed locations.

- Load balancing to distribute workloads across redundant servers.

Challenges and Trade-Offs in Redundancy

While redundancy improves reliability, it also introduces challenges and trade-offs:

1. Cost

Redundancy increases material and development costs. Engineers must carefully evaluate the cost-benefit ratio for each application.

2. Complexity

Adding redundancy increases system complexity, which can lead to design errors or unexpected failure modes.

3. Power Consumption

Redundant components consume additional power, which can be a limitation in battery-powered systems.

4. Latency

Fault detection and recovery mechanisms can introduce latency, which may be unacceptable in real-time systems.

Future Trends in Redundancy for Embedded Systems

1. AI-Powered Fault Detection

Machine learning algorithms can analyze system behavior to predict and mitigate failures before they occur, enhancing the effectiveness of redundancy mechanisms.

2. Dynamic Redundancy

Future systems may implement dynamic redundancy, enabling components to reconfigure themselves based on operational conditions.

Example:

A robotic arm could dynamically allocate redundant motors to critical joints during high-stress operations.

3. Hardware-Assisted Redundancy

Modern FPGAs and SoCs integrate hardware features for redundancy, such as error-correcting code (ECC) memory and built-in self-test (BIST) mechanisms.

Conclusion

Designing with redundancy is an essential strategy for improving reliability in critical embedded systems. By incorporating hardware, software, data, and functional redundancy, engineers can create systems that are robust, fault-tolerant, and capable of operating under the most demanding conditions.

However, redundancy comes with trade-offs in cost, complexity, and power consumption. By carefully analyzing system requirements, identifying critical components, and leveraging best practices, embedded engineers can achieve an optimal balance between reliability and resource efficiency.

Redundancy isn’t just about preparing for failure—it’s about designing systems that inspire confidence, perform reliably, and stand the test of time in critical applications.