In today’s technology-driven world, embedded systems play a crucial role in various industries, including automotive, aerospace, medical, and consumer electronics. Ensuring safety and reliability in these systems is paramount.

Safety standards and certifications provide a framework for developing safe and reliable embedded systems, helping to mitigate risks associated with potential failures and accidents. They not only aid in maintaining product quality but also contribute to consumer trust and confidence in the end product.

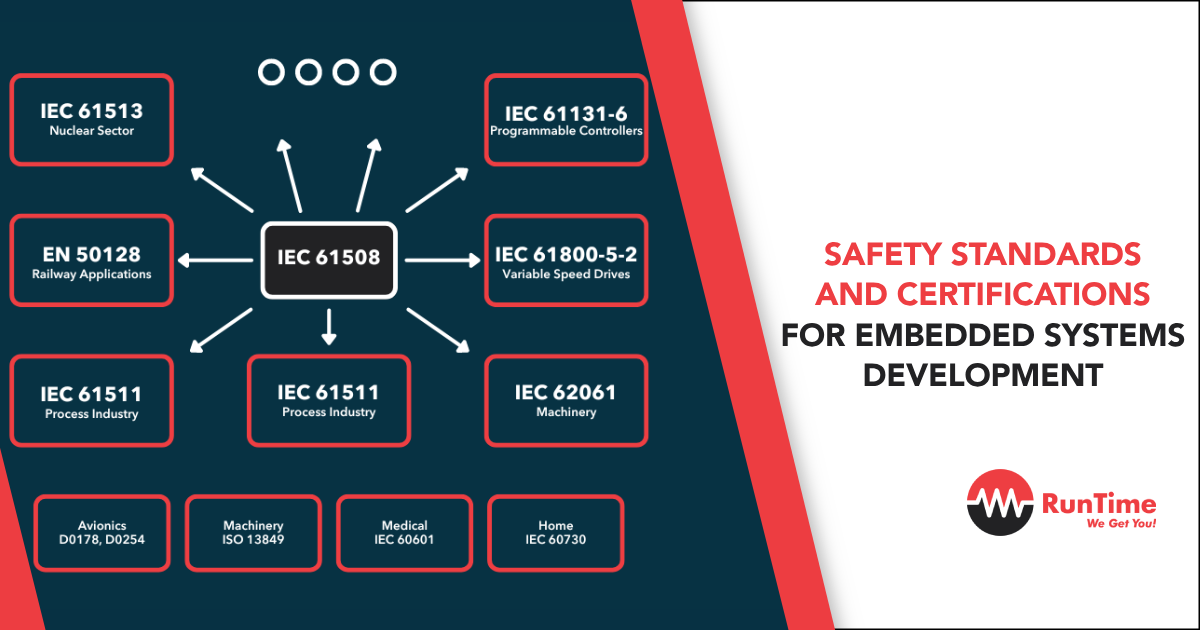

This article aims to provide an in-depth understanding of the safety standards and certifications relevant to embedded systems development. We will discuss some of the most common safety standards, including ISO 26262, IEC 61508, DO-178C, IEC 62304, and EN 50128, as well as the certifications that ensure compliance with these standards.

Furthermore, we will explore the role of safety standards and certifications in product development, including their impact on product safety, risk reduction, market acceptance, and legal aspects. Additionally, we will delve into the challenges and solutions in meeting these safety standards, and conclude with case studies showcasing successful implementation of safety standards and certifications in embedded systems development.

Common Safety Standards for Embedded Systems

ISO 26262 — Road Vehicles — Functional Safety

ISO 26262 is an international standard for functional safety in automotive electronic and electrical systems. It focuses on the entire lifecycle of safety-critical components, from concept to decommissioning.

The standard covers various aspects of automotive safety, including hardware, software, and system-level design. Compliance with ISO 26262 helps ensure that potential hazards are identified, assessed, and managed throughout the development process, thus reducing the risk of accidents and failures.

IEC 61508 — Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems

IEC 61508 is a generic standard for functional safety across various industries, including process control, machinery, and railway signaling systems. It applies to electrical, electronic, and programmable electronic safety-related systems and provides a framework for managing safety throughout the entire system lifecycle.

Compliance with IEC 61508 helps ensure that safety functions are performed correctly and consistently, minimizing the risk of accidents and incidents.

DO-178C — Software Considerations in Airborne Systems and Equipment Certification

DO-178C is an industry standard for the development of software used in airborne systems and equipment. It provides guidelines for ensuring the safety and reliability of software components and helps demonstrate compliance with airworthiness requirements.

The standard covers various aspects of software development, including planning, design, coding, testing, and verification. Compliance with DO-178C ensures that software used in airborne systems meets stringent safety and performance requirements.

IEC 62304 — Medical Device Software — Software Life Cycle Processes

IEC 62304 is an international standard for the development of software used in medical devices. It provides a framework for managing software development processes, ensuring that medical device software meets safety and performance requirements.

The standard covers the entire software lifecycle, from planning and design to maintenance and decommissioning. Compliance with IEC 62304 helps ensure that medical device software is developed, tested, and maintained in a manner that minimizes risks to patients and users.

EN 50128 — Railway Applications — Communication, Signaling, and Processing Systems

EN 50128 is a European standard for the development of software used in railway applications, including communication, signaling, and processing systems. It provides guidelines for ensuring the safety and reliability of software components used in railway systems and helps demonstrate compliance with safety requirements.

The standard covers various aspects of software development, including planning, design, coding, testing, and verification. Compliance with EN 50128 ensures that software used in railway systems meets stringent safety and performance requirements.

Other Relevant Safety Standards and Their Applications

There are numerous other safety standards specific to different industries and applications. These standards help ensure the safety and reliability of embedded systems in various sectors, such as aerospace, automotive, medical, railway, and industrial automation. Compliance with these standards is essential for meeting industry-specific safety requirements and for gaining market acceptance of the end product. It is crucial for developers and engineers to identify and adhere to the relevant safety standards for their specific embedded system applications.

Certifications for Embedded Systems Development

Introduction to Certifications in Embedded Systems

Certifications in embedded systems development serve as a testament to the safety and reliability of a product. They demonstrate compliance with relevant safety standards and provide assurance to customers, regulators, and other stakeholders that the product meets the necessary safety requirements. Acquiring certifications can be a complex process, as it typically involves rigorous testing, documentation, and verification by accredited certification bodies.

The Role of Certifications in Ensuring Compliance with Safety Standards

Certifications play a crucial role in ensuring compliance with safety standards. They provide a structured process for verifying that a product meets the specified safety requirements and functions as intended.

This verification process typically involves a thorough examination of the product’s design, manufacturing, testing, and documentation. By obtaining certifications, manufacturers can demonstrate their commitment to safety and gain the trust of customers, regulators, and other stakeholders.

Popular Certifications for Embedded Systems Development

- TÜV SÜD certification: TÜV SÜD is a globally recognized certification body that offers a wide range of certifications for embedded systems development. This includes compliance with safety standards such as ISO 26262, IEC 61508, and IEC 62304. TÜV SÜD certification provides assurance that a product meets the necessary safety and performance requirements.

- UL certification: Underwriters Laboratories (UL) is an independent safety certification organization that evaluates products for compliance with various safety standards. UL certification is widely recognized and accepted in the global market, demonstrating a product’s commitment to safety and reliability.

- IECEx certification: IECEx is an international certification scheme for equipment used in explosive atmospheres. It is based on the IEC 60079 series of standards and provides a globally accepted certification for products used in hazardous environments. Obtaining IECEx certification ensures that a product meets the necessary safety requirements for use in potentially explosive environments.

- ATEX certification: ATEX is a European certification scheme for equipment used in explosive atmospheres. It is based on the EU’s ATEX Directive and provides a certification framework for products used in hazardous environments within the European Union. ATEX certification ensures that a product meets the necessary safety requirements for use in potentially explosive environments within the EU.

How to Choose the Right Certification for Your Embedded Systems Project

- Choosing the right certification for your embedded systems project depends on several factors, including the target market, industry sector, and specific safety requirements of the product. Some key considerations when selecting a certification include:

- Understanding the safety standards and requirements relevant to your industry and product

- Identifying the target markets and regions for your product

- Considering the cost, time, and resources required to obtain the certification valuating the reputation and credibility of the certification body

By carefully considering these factors and consulting with industry experts, you can select the most appropriate certification for your embedded systems project, ensuring compliance with safety standards and increasing the likelihood of market acceptance.

The Role of Safety Standards and Certifications in Product Development

Ensuring Product Safety and Reliability

Safety standards and certifications play a vital role in ensuring product safety and reliability. By adhering to established safety standards, developers and manufacturers can systematically identify, assess, and mitigate potential hazards and risks associated with their products. Certifications act as an additional layer of assurance, validating that a product meets the required safety requirements and performs its intended function reliably.

Reducing the Risk of Accidents and Failures

Compliance with safety standards and certifications helps to reduce the risk of accidents and failures in embedded systems. These standards provide a comprehensive framework for addressing potential hazards and risks throughout the product development process. By following the guidelines and best practices outlined in safety standards, developers can minimize the likelihood of accidents and system failures, ultimately enhancing the safety and dependability of their products.

Facilitating International Trade and Market Acceptance

Safety standards and certifications are crucial for facilitating international trade and market acceptance. By complying with globally recognized safety standards, manufacturers can demonstrate their commitment to safety and quality, making their products more appealing to customers, regulators, and other stakeholders. Certifications, in particular, serve as a universally accepted validation of a product’s safety and performance, simplifying the process of entering new markets and gaining regulatory approval.

Avoiding Legal Issues and Liability Claims

Adherence to safety standards and certifications can help manufacturers avoid legal issues and liability claims associated with product failures and accidents. By demonstrating compliance with established safety standards, manufacturers can show that they have taken the necessary steps to ensure the safety and reliability of their products. This can be invaluable in the event of a product-related accident, as it may help to mitigate liability claims and protect the manufacturer from potential legal repercussions.

Integrating Safety Standards into the Development Process

Understanding the Safety Requirements of Your Specific Industry

Each industry has unique safety requirements that must be addressed during the development of embedded systems. It is crucial for developers and engineers to understand the specific safety standards and regulations applicable to their industry. This understanding enables them to develop products that meet the necessary safety and performance requirements, ultimately ensuring the safety and reliability of their systems.

Incorporating Safety Standards Early in the Development Process

Integrating safety standards into the development process from the outset is essential for creating safe and reliable embedded systems. By considering safety requirements during the initial design stages, developers can proactively identify and address potential hazards and risks, ultimately reducing the likelihood of accidents and system failures.

Early integration of safety standards also allows for more efficient development processes, as it minimizes the need for costly redesigns and retesting later in the development cycle.

Following Best Practices and Guidelines for Safety-Critical Systems Development

Adhering to best practices and guidelines for safety-critical systems development is vital for ensuring the safety and reliability of embedded systems. These best practices include rigorous design methodologies, thorough testing and verification processes, and comprehensive documentation of development activities. By following these guidelines, developers can create embedded systems that meet the stringent safety requirements of their respective industries and minimize the risk of accidents and failures.

Implementing Processes for Ongoing Safety Compliance and Maintenance

Ensuring ongoing safety compliance and maintenance is essential for the continued safety and reliability of embedded systems. This includes implementing processes for monitoring system performance, conducting regular safety assessments, and addressing any identified safety issues or vulnerabilities. By maintaining a proactive approach to safety compliance and maintenance, developers can help ensure that their embedded systems continue to meet the necessary safety requirements and perform their intended functions reliably throughout their lifecycle.

Challenges and Solutions in Meeting Safety Standards and Certifications

Common Challenges in Achieving Compliance with Safety Standards

Developers and manufacturers often face several challenges in achieving compliance with safety standards and certifications. These challenges may include a lack of understanding of the relevant safety requirements, limited resources for addressing safety concerns, and difficulties in ensuring consistent safety practices across different development teams. Additionally, the complexity of embedded systems, coupled with the stringent requirements of safety standards, can make achieving compliance a daunting task.

Strategies for Overcoming These Challenges

- Training and education for engineers and developers: Ensuring that engineers and developers have a thorough understanding of the relevant safety standards and requirements are crucial for achieving compliance. Providing training and education on safety best practices, guidelines, and tools can help equip them with the knowledge and skills necessary to develop safe and reliable embedded systems.

- Collaboration between hardware, software, and system engineering teams: Effective collaboration between hardware, software, and system engineering teams is essential for addressing safety concerns and ensuring compliance with safety standards. By fostering a collaborative environment, organizations can ensure that safety considerations are integrated throughout the entire development process, resulting in a more cohesive and robust system.

- Utilizing safety-focused development tools and methodologies: Employing safety-focused development tools and methodologies can help streamline the process of achieving compliance with safety standards. These tools and methodologies can assist in the identification, assessment, and management of potential hazards and risks, ultimately contributing to the development of safer embedded systems.

- Seeking assistance from industry experts and certification bodies: Engaging with industry experts and certification bodies can provide valuable guidance and support in achieving compliance with safety standards and certifications. These experts can offer insights into best practices, common challenges, and potential solutions, helping organizations navigate the complex landscape of safety compliance more effectively.

Case Studies: Successful Implementation of Safety Standards and Certifications in Embedded Systems

Examples of Products that Have Successfully Achieved Safety Certification

Various products across different industries have successfully achieved safety certifications, demonstrating their commitment to safety and reliability. Examples include:

- Automotive electronic control units (ECUs) certified to ISO 26262, ensuring functional safety in road vehicles.

- Airborne equipment and systems that have obtained DO-178C certification, demonstrating compliance with stringent aviation safety requirements.

- Medical devices with embedded software certified to IEC 62304, ensuring the safety and reliability of software components in life-critical applications.

- Railway communication, signaling, and processing systems that have achieved EN 50128 certification, demonstrating adherence to safety requirements in the railway industry.

Lessons Learned from These Case Studies

- These case studies highlight several important lessons for developers and manufacturers seeking to achieve safety certifications for their embedded systems:

- A thorough understanding of the relevant safety standards and requirements is essential for ensuring compliance.

- Effective collaboration between hardware, software, and system engineering teams is crucial for addressing safety concerns and achieving certification.

- Implementing safety-focused development tools and methodologies can streamline the process of achieving compliance and result in safer products.

- Engaging with industry experts and certification bodies can provide valuable guidance and support throughout the certification process.

How These Examples Demonstrate the Benefits of Adhering to Safety Standards and Certifications

The successful implementation of safety standards and certifications in these case studies demonstrates the numerous benefits of adhering to such requirements. By achieving certification, these products have gained a competitive edge in the market, as customers and regulators recognize their commitment to safety and reliability.

Additionally, compliance with safety standards helps to reduce the risk of accidents and system failures, ultimately protecting the reputation of the manufacturers and contributing to the overall safety of end-users. These examples serve as a testament to the importance of prioritizing safety compliance in the development of embedded systems.

Conclusion

As demonstrated throughout this article, safety standards and certifications hold significant importance in embedded systems development. They provide a structured framework for ensuring safety and reliability, helping developers and manufacturers mitigate potential hazards and risks associated with their products. Furthermore, compliance with these standards and certifications can contribute to the overall success and market acceptance of embedded systems.

Adhering to safety requirements brings numerous benefits for both businesses and end-users. For businesses, compliance with safety standards can improve market competitiveness, enhance customer trust, and reduce the risk of legal issues and liability claims. For end-users, products that meet safety requirements offer enhanced safety and reliability, providing peace of mind when using these embedded systems in various applications.

In conclusion, we encourage developers and manufacturers to prioritize safety compliance in their future embedded systems projects. By understanding and adhering to the relevant safety standards, incorporating safety-focused development processes, and seeking the appropriate certifications, businesses can create products that not only meet the stringent safety requirements of their respective industries but also contribute to the overall safety and well-being of end-users.

At RunTime Recruitment, we understand the importance of safety compliance in embedded systems development and strive to provide our clients and candidates with the necessary resources and expertise to meet these requirements.

Hire Highly-Skilled Engineers with RunTime Recruitment

Our expert team of engineers-turned-recruiters offers in-depth technical recruiting knowledge in the engineering industry.

If your company is looking to recruit highly-skilled engineers worldwide, contact us today and we will do the sourcing for you. Or if you’re an engineer looking for new opportunities, you can check RunTime Recruitment’s job site for job vacancies